Inform®

Cored Wire

Innovative solution for precise magnesium and inoculation treatment.

In-mold Inoculants

Germalloy®, Optigran® and SMW-Formling®

Most effective inoculation directly in the mold.

Master Alloy / Magnesium treatment with master alloy

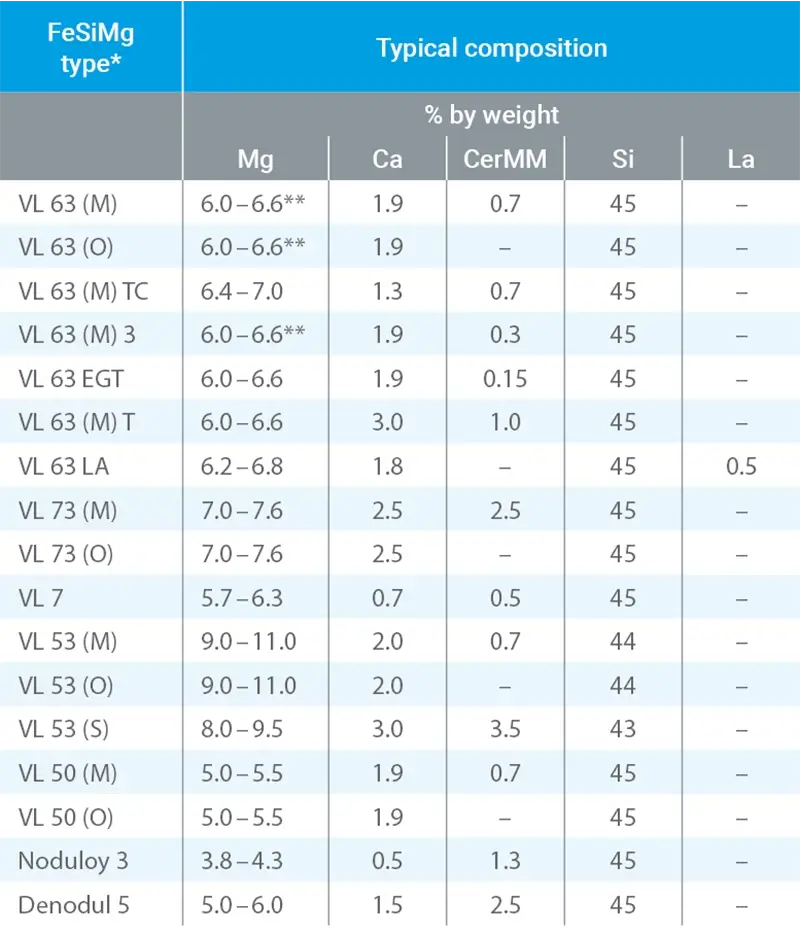

FeSiMg and NiMg

Personal interaction with our customers is important for us to find the most effective master alloy for every need. Questions and concerns can be resolved easily and quickly in a direct conversation. Contact us – our service team is here for you.

Your Benefits

- Our alloys achieve the highest quality standards.

- Flexible, customer-specific adjustment of essential elements such as Mg, Ca or RE.

Methods for Magnesium Treatment with Master Alloy

Master Alloys for Magnesium Treatment

* other specifications on request

** exception for grain size 0.125 – 1mm: 5.4 – 6.0% Mg

* other specifications on request

Inform Cored Wires

INFORM M Cored Wire

INFORM M cored wires are a very efficient and reliable method for magnesium treatment. The cored wires are available in different diameters. The wire feeding process is very easy to handle and ideal for automated processes. INFORM M cored wires are produced with the utmost care and according to high quality standards.

Magnesium treatment with cored wires offers great flexibility regarding changing initial conditions such as sulfur content, treatment temperature, and iron quantity. This will enable for consistent Mg values despite varying initial sulfur levels and treatment temperatures. Finally, treatment costs can be reduced. Using targeted suction, the process is also very environmentally friendly.

Classification of Mg Treatment Wires

* SA = initial sulfur content

Your Benefits

- Optimized and customized composition for your specific foundry requirements with INFORM M cored wires.

- The cored wire process allows precise dosing and low addition quantities.

- The cored wire process is easy to handle and automate.

- Magnesium treatment with INFORM M offers good traceability and documentation.

Improvement of working conditions & significant cost savings

A foundry group planned to build a new foundry for large wind power components weighing up to approx. 30 t. The Mg treatment process was intended to improve working conditions for employees, but also to be more cost-effective than the previous process using master alloys. Furthermore, the customer targeted better process documentation and the ability to react more flexibly to initial conditions. Another challenge was the time limit for Mg treatment.

Profile

Location:Europe

Material:GJS

Capacity:20,000t / year; hand molding

Castings:Hubs, machine carriers

Markets:Wind energy

Inoculants

Ladle and in-stream inoculants as well as inoculant wires for various applications

Inoculating the melt enables a targeted influence on parameters as solidification behavior or microstructure formation of the casting. Our portfolio of ladle and in-stream inoculants, as well as inoculant wires, covers various application areas in gray cast iron (GJL), ductile iron (GJS), and compacted graphite iron (CGI). Each inoculant has specific compositions or characteristics to achieve the desired effects. Our inoculants are produced under strict quality control.

Your Benefits

- Very good dissolution behavior.

- High efficiency and low consumption.

- Uniform graphite formation.

- Improvement of mechanical properties.

Methods for Inoculant Addition

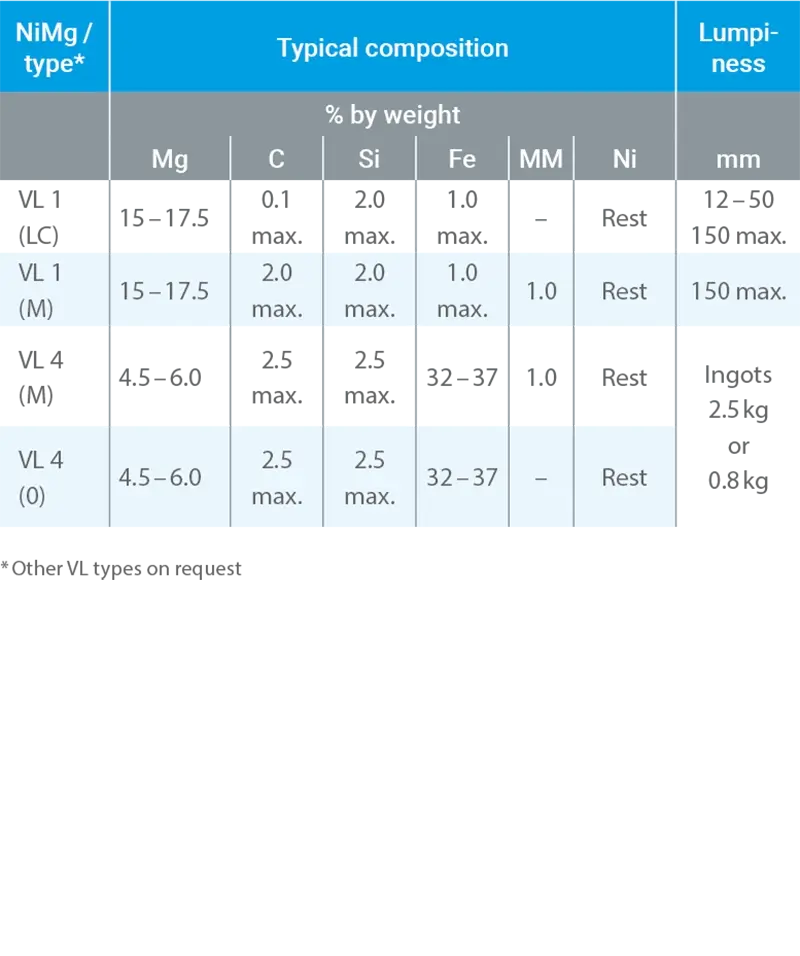

Inoculating Elements and Recommended Application Area

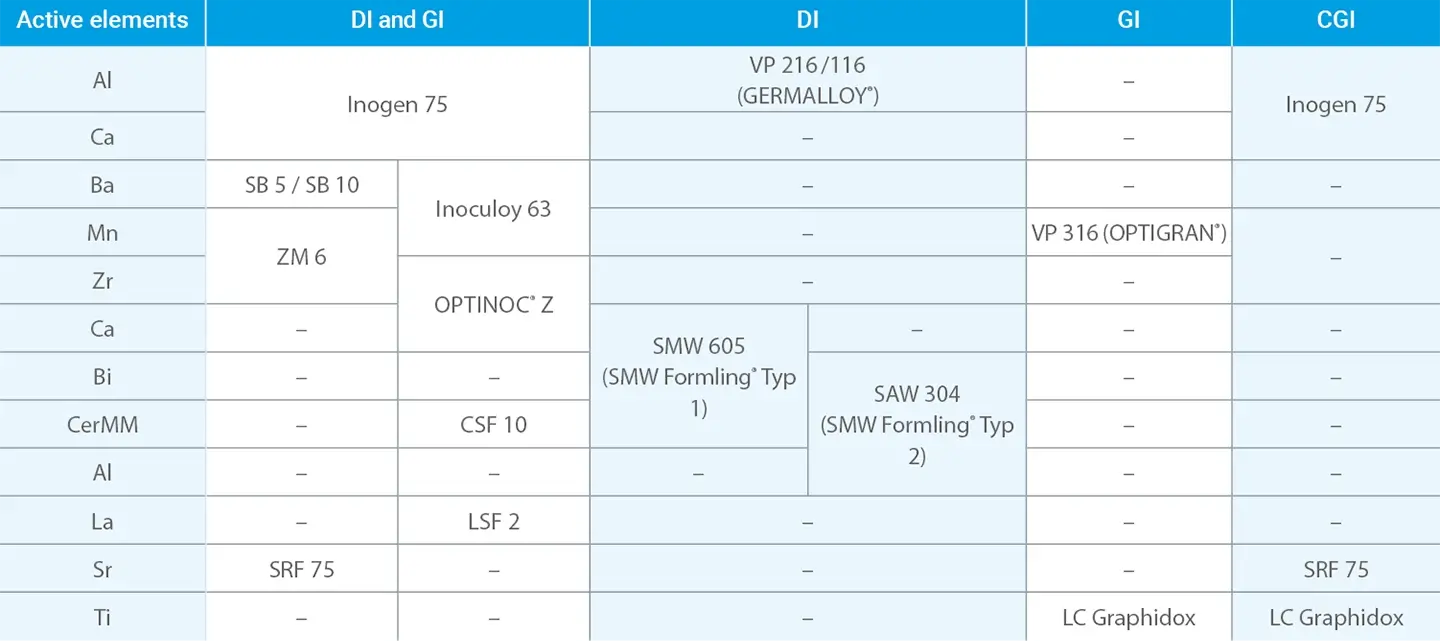

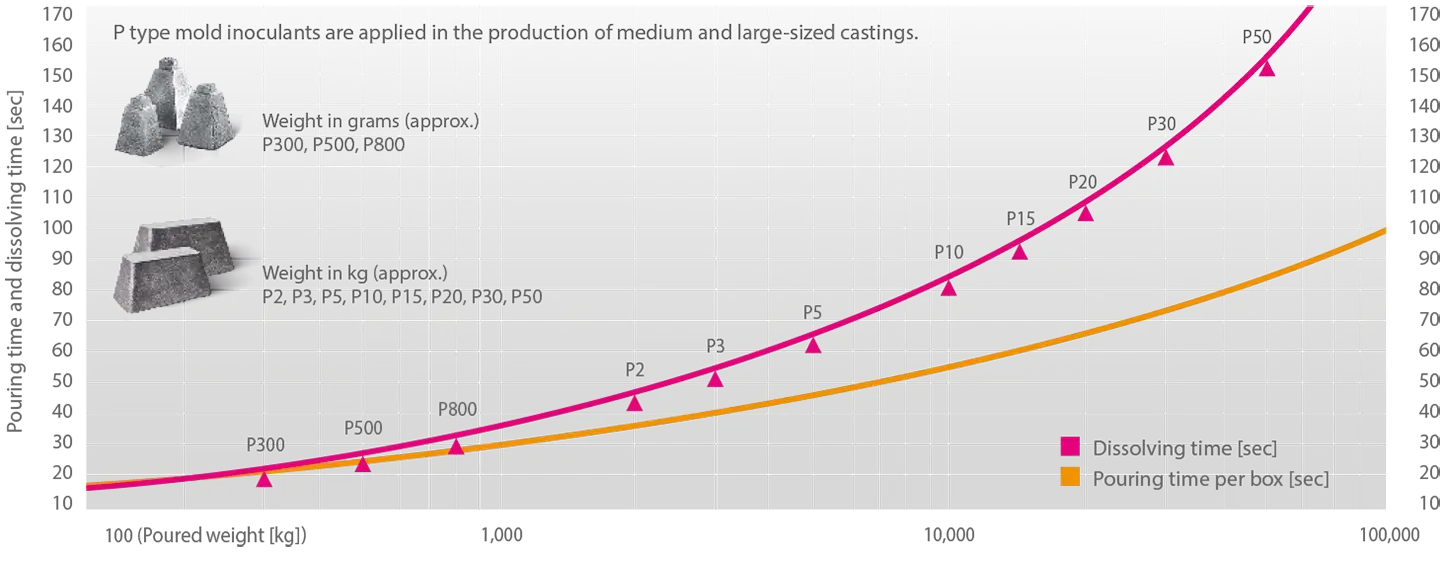

In-mold Inoculants

In-mold inoculation with GERMALLOY, SMW Formlinge and OP-TIGRAN

The in-mold inoculants GERMALLOY and SMW Formlinge are cast inoculant blocks used for in-mold inoculation of ductile iron. They are placed either in the gating system of the mold or, for large casting molds, in the pouring basin. The in-mold inoculant GERMALLOY is used to improve graphite nodularity and optimize mechanical properties. SMW Formlinge, in combination with GERMALLOY, increase the nodule count and prevent the formation of chunky graphite. OPTIGRAN is the in-mold inoculant for gray cast iron. It serves to achieve finer, evenly distributed A-graphite.

Your Benefits

- Inoculant quantity precisely adapted to the iron amount.

- No contact with the atmosphere during dissolution, therefore no oxidation.

- No fading of the inoculation effect.

- Higher nodule count and better nodularity (GJS).

- EN-GJS-400-15 & EN-GJS-400-18 in as-cast condition.

- SMW Formling prevents chunky graphite.

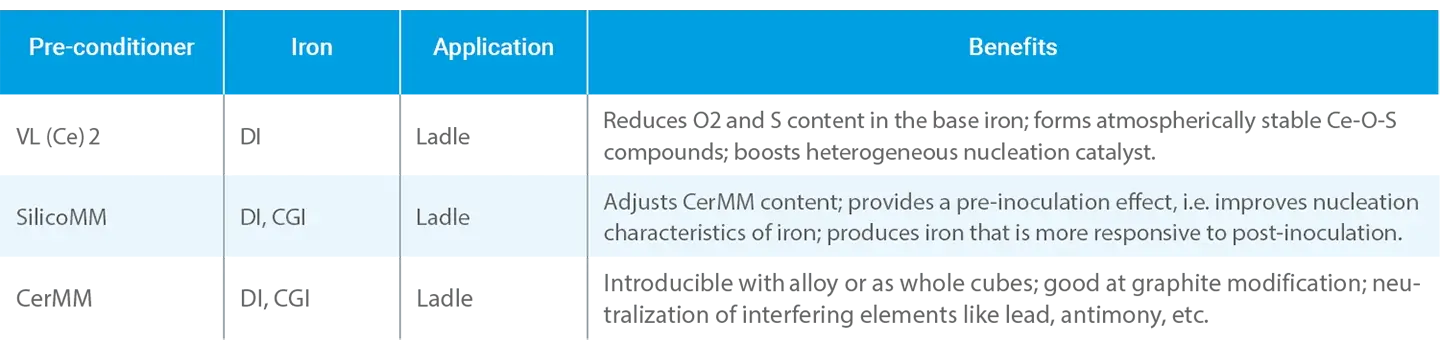

Preconditioning Agents

Preconditioning of the melt for optimized base iron

Preconditioning of the melt ensures consistent conditions in liquid metal. For example, consistent levels of oxygen and sulfur are important, especially for subsequent Mg treatment processes. Achieving process stability, producing a uniform base iron, and improving the nucleation potential of the molten metal are the most important factors.

Your Benefits

- Improvement of process stability.

- Ensuring a uniform base iron.

Products for Pre-treatment

Melt Cleaners

Melt Cleaners

DISPERSIT represents a new process for the metallurgical cleaning of iron melts. It reduces the surface tension of the melt and promotes the coagulation of foreign particles and reaction products, allowing them to float up more quickly. Furthermore, DISPERSIT reduces the deposition of reaction products on ladle and furnace linings as well as in pouring equipment.

By using the new melt cleaner, the addition of Mg-containing master alloys in the production of ductile iron can be reduced. For example, 1 kg of DISPERSIT typically replaces 1 – 2 kg of an FeSiMg 5 master alloy. For other master alloys, there are corresponding empirical values. By using the melt cleaner DISPERSIT, it has often been possible to reduce scrap caused by dross and inclusions by over 50%.

Your Benefits

- DISPERSIT serves for preconditioning the melt.

- The melt cleaner reduces on the ladle and furnace lining.

- Reduction of dross and slag inclusions.